Carburetor Icing And Heat

Carburetor Icing And Heat

Carburetor icing is an icing condition which can affect any carburetor under certain atmospheric conditions. While it applies to all carburetors, it is only really a problem in association with piston-powered aircraft, particularly small single-engined light aircraft. Carburetor heat (usually abbreviated to ‘carb heat’) is a system used in piston-powered light aircraft to help prevent or clear carburetor icing. It is usually manually controlled by the pilot. It consists of a flap which diverts warm air from around the exhaust manifold into the engine’s air intake. The warmer air will usually clear any icing present within the carburetor. Applying carb heat as a matter of routine is built into numerous in-flight and pre-landing checks. Engines equipped with fuel injection do not require carb heat or an analogous system as they are not prone to icing. Some car intake manifolds had this, for the same reasons that aircraft do. Many Chevrolets from the early 50’s had it, but so do a number of aftermarket performance manifolds from Clifford Performance.

Aircraft powered by carbureted engines are equipped with carburetor heat systems to overcome the icing problem. In cars, carb icing can occasionally be a nuisance but isn’t usually a huge problem, as the inlet manifold and parts of the carburetor often have warm water circulating through them from the water cooling system. Motorcycles can also suffer from carb icing, although some engine designs are more prone to it than others. Air cooled engines may be more prone to icing, though it is mostly in aircraft that the phenomenon is a significant problem.

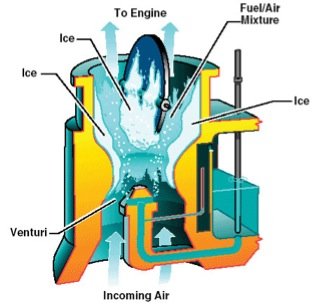

Carb icing occurs when there is humid air, and the temperature drop in the venturi causes the water vapour to freeze. The ice will form on the surfaces of the carburetor throat, further restricting it. This may increase the venturi effect initially, but eventually restricts airflow, perhaps even causing a complete blockage of the carburetor. Icing may also cause jamming of the mechanical parts of the carburetor, such as the throttle butterfly valve. For information about when there is a chance of carburetor icing, consult a graph (compiled by the British CAA) that can be downloaded here: Carburetor icing chart.

Icing occurs in certain conditions due to the venturi within the carburetor, which raises the velocity of the air in the carburetor, which lowers its pressure (see Bernoulli’s principle) and hence temperature (Boyle’s Law). If the outside air is already at a low temperature, the temperature in the carburetor can drop below the freezing point of water, and if the air is humid, ice can form inside the carburetor, narrowing the aperture of the throat, which can create an even stronger venturi effect, and so forth. If left unchecked, the carburetor will eventually malfunction which will cause an engine failure, an emergency situation. Temperature drops of 20 degrees C or more are often encountered within the carburetor, and so icing can occur even on relatively warm days. Also, the adiabatic lapse rate (temperature drop) is around 4 degrees C per thousand feet, so it is really the humidity of the air which is the more important indicator of potential icing conditions.

Perhaps paradoxically, winter flying is often less prone to icing, since cold weather is rarely associated with high humidity, and the air temperature can drop so far below freezing that there can be little or no water vapour in the air to begin with. Diverting warm air into the intake will usually clear any icing present, though in some conditions still may not be sufficient. The wise pilot will not attempt to fly into known icing conditions if his aircraft is not equipped to deal with it. The diversion of warm air into the intake reduces the thermodynamic efficiency of the engine, which will be manifest as a slight reduction in power while carb heat is applied. The reduction in power indicates to the pilot that there is no icing present, a reassuring piece of information. If there is icing, applying carb heat may not show this initial reduction, and as the ice clears there may be an increase in power. Again, the pilot will note this as evidence that icing conditions are present.

If carb icing results in an engine stoppage, one of the first things the pilot will do is apply carb heat in an attempt to clear the icing, though as the engine will not be running, it is possible that the exhaust will cool sufficiently quickly that clearing the icing will not be possible. In any case the pilot will be carrying out the emergency landing procedure, including a possible engine restart. The outcome depends on the conditions, prompt action and skill. Again, avoiding icing is far better than trying to clear it in an emergency.

SU carburetors

SU carburetors (named for Skinners Union, the company which produced them) were a brand of side draft carburetor widely used in British (Austin, Morris, Triumph, MG) and Swedish (Volvo, Saab 99) automobiles for much of the twentieth century. Originally designed and patented by George Herbert Skinner in 1905, they remained in production through to the 1980s by which time they had become part of the BMC/British Leyland Group. Hitachi also built carburetors based on the SU design which were used on the Datsun 240Z and other Datsun Cars. While these look the same, they are different enough that needles (see below) are the only part that fits both.

Some great references can also be found in the Books Reference page.